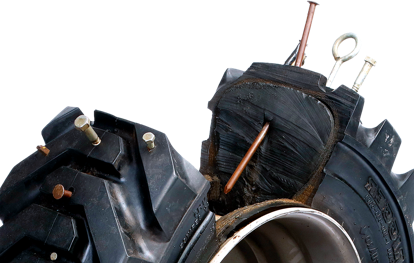

Flat proof tires

Eliminate Flat Tires Forever!

TyrFil™ offers the smoothest flatproofed ride in demanding and hazardous Off-the-Road (OTR) applications, including the construction, waste management, mining, municipality, military and rental equipment markets.

Weight

Estimator

Profit

Analysis

Resource

Library

Who We Serve

Aftermarket Dealers

Equipment Owners

EQuipment Operators

Rental Companies

Military Applications

TIRE FLATPROOFING & PRODUCTIVITY TECHNOLOGIES

TyrFil™ Flatproofing

TyrFil™ is a polyurethane liquid that is pumped into pneumatic tires to replace air with a resilient, synthetic elastomer core that eliminates dangerous and costly tire flats on off-the-road (OTR) equipment.

TLC Tire and Rim Protection™

TLC™ promotes safety, reduces downtime and extends the life of OTR tires and rims.

ReSeal™ Tire Sealant

ReSeal™ industrial strength tire sealant offers light-weight tire protection when your equipment is exposed to harsh conditions.

TyrFil Equipment

Carlisle TyrFil™ offers proven pumping equipment technology – over 100MM pounds pumped annually.

The Global Leader

in Flatproofing

Technologies

Protecting the world from flat tires and increasing productivity for more than 45 years!

DON’T ENDURE ANOTHER ROUGH RIDE

“Solid Shock” refers to the harsh impact of g-force vibration emitted to heavy industrial vehicle operators and their equipment from solid aperture tires. Not only is Solid Shock a major source of wear and tear on machines, but it’s also a leading cause of Whole Body Vibration.